3D printing is revolutionizing the way various industries develop and refine their designs. The key for manufacturers to understand is the primary purpose and limitations of this service. At its best, this process is a cost-effective and efficient method for creating and testing prototypes before committing to production tooling.

3D Printing: Definition, Evolution & Role in Engineering

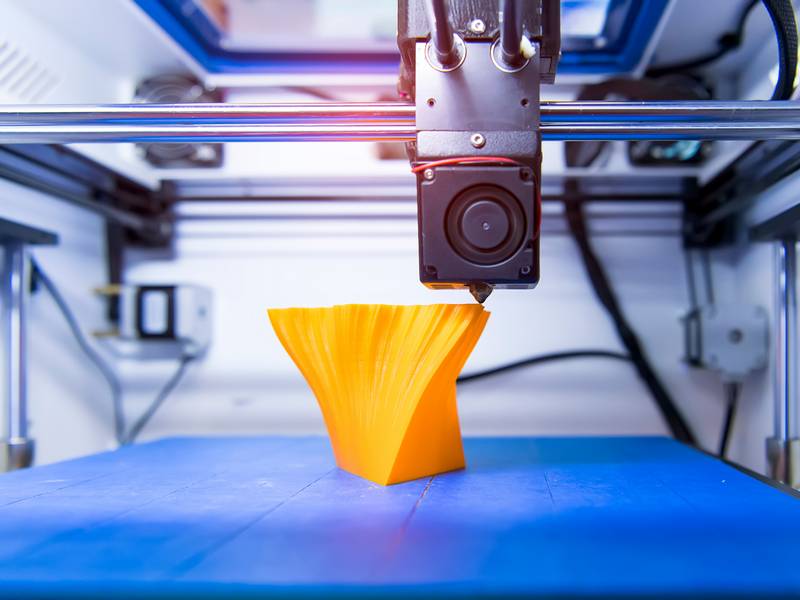

The manufacturing process known as 3D printing converts digital designs into physical objects. The 3D printer adds materials where they’re needed to build objects layer by layer. It’s also known as “additive manufacturing” in specific industries. 3D printing works in the opposite way of traditional manufacturing, where material is added layer by layer. Additive manufacturing facilities create intricate shapes that are difficult or costly to produce using conventional manufacturing methods.

3D printing became a mainstream part of the engineering and product development industry in the early to mid-2000s. It gained significant momentum and wider adoption in the 2010s, following the expiration of patents, which made the technologies more accessible. During this time, machine costs decreased while additive manufacturing capabilities continued to improve. Its recognition increased when President Barack Obama mentioned its potential in his 2013 State of the Union address.

Today, 3D printing has etched out its place in the product development lifecycle. It quickly transforms digital concepts into physical prototypes. This makes it a cost-effective and efficient way to test those items for design flaws. Once the prototype is accepted, companies typically commit to traditional manufacturing methods. The true benefit of 3D printing lies in its ability to streamline the path from a concept to a market-ready product.

Additive Manufacturing:

While 3D printing is excellent in its assigned role, it’s not a perfect manufacturing process. For example, some people mistakenly believe that any 3D model can be printed perfectly as is. The truth is that these designs sometimes need specific optimization for additive manufacturing. Several factors that determine this include wall thickness, overhangs, and support structures, which can be complex to prepare. Other limitations associated with 3D printing include:

- Material Limitations: 3D printable materials, as not all materials are suitable for this process.

- Post-Processing: Many 3D printed parts require the removal of support structures, as well as sanding, polishing, and painting. This adds time and increases costs.

- Accuracy & Tolerances: Print quality may deviate from the original design due to variations in printer, material, and settings.

- Print Speed & Part Size: Printing extensive or detailed parts can take many hours or even days to produce.

- Additional Costs: This includes material, machine time, labor, and the expertise needed to manage the 3D printing process.

While these aspects of 3D printing are essential to be aware of, this form of manufacturing is still highly effective for many companies. Every manufacturer is seeking cost-effective ways to produce prototypes or small batches, and additive manufacturing serves this niche. Its unique capabilities speed up design cycles while reducing development risks, which allows for accessible innovation. These qualities suggest that 3D printing will continue to be a valuable tool in today’s competitive landscape.

3D Printing: AlphaUSA is Your Experiences Product Development Solution

Are you looking for quick, reliable, and affordable 3D printing? AlphaUSA is your total solution. Thanks to our professional expertise, we can bring your ideas to life quickly in most cases. Our exceptional team is here to deliver high-quality results with minimal issues. We work with you to iterate through your designs and offer quick adjustments based on feedback and testing. Call (734) 523-1000 or contact us online to learn more about our 3D printing.